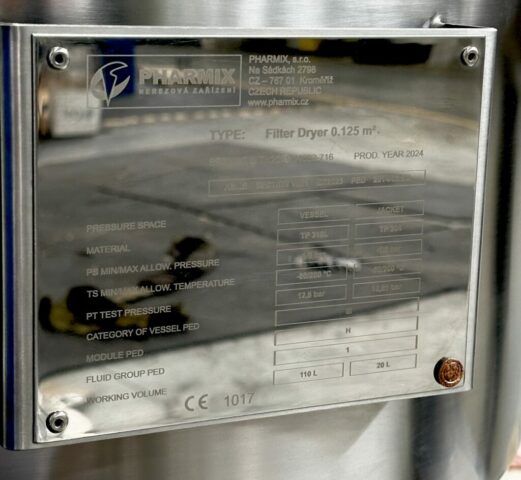

New realisation: Agitated Nutsche Filter Dryer (ANFD) 0,125 m²

We are pleased to announce the completion of a new project for a 0.125 m² mixing Nutsche filter and drying system. This dedicated facility represents the latest addition to our product portfolio for the pharmaceutical and chemical industries.

The equipment was manufactured for a UK client, and is another example of our ability to supply high quality products, even for international markets with stringent requirements for standards, documentation and technical performance.

What is a Nutsche mixing filter and drying system?

It is a multi-functional device that combines the functions of filtration, washing and drying of products in one vessel. The system allows the processing of solids in the liquid phase followed by drying, which significantly streamlines the production process. Nutsche filters are ideal for applications where high product purity, minimal residual solvent and consistent particle size are required.

Technical specifications of our solution:

- Filter area size: 0,125 m²

- Standards and certifications:

- Production according to ASME VIII, Div. 1 (2023)

- PED 2014/68/EU – Category 4, Module H/H1

- Complete set of certifications according to EN 10204:3.1, WPS, WPQ, NDT, material approvals

- Pressure vessel category: 4

- Conformity assessment: module H/H1

- Materiálové provedení:

- Product contact parts: AISI 316L

- Other parts: AISI 304L

- Design pressure:

- Vessel: up to 6 barg

- Heating jacket: up to 6 barg

- Operating temperature: -60/+200 °C

- Surface finish:

- Inner surface and parts in contact with product: Ra < 0.4 µm

- Outer surface: Ra < 0.8 µm

- Directional grinding to specification

Quality and testing:

Each of our products undergoes stringent quality controls. This filtering and drying system has been subjected to:

- Hydrostatic pressure tests of the vessel and heating jacket

- X-ray weld tests

- Capillary weld tests and specified surfaces

- Surface roughness measurements to BS 1134

The entire manufacturing process was documented to the highest standards including:

- Material Certificates 3.1 to EN 10204

- Welding Protocols (WPS, WPQ)

- EU Declaration of Conformity (PED)

- Other certificates and protocols

For more information about our capabilities in the manufacture of filtration and drying systems, please contact us.